Introduction

With 28 years of food ingredient expertise, Runxin presents Food Grade Sodium Hyaluronate Solutions—comprehensive strategies for food and beverage applications requiring certified quality and safety. This guide addresses food-specific formulation challenges while providing reliable solutions for diverse culinary applications.

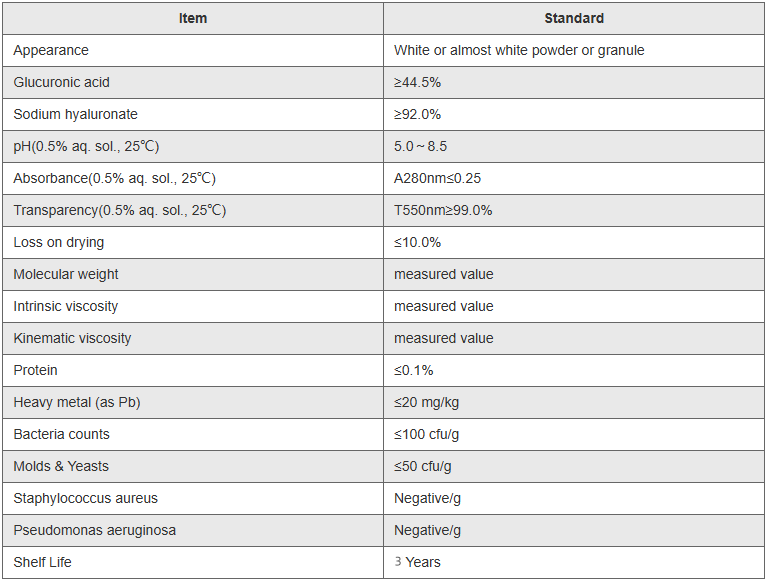

Technical Specifications & Food Compliance

Food-grade purity meeting international standards

Multiple molecular weights available (50kDa-2000kDa)

Optimized for various food processing conditions

Full compliance with global food safety regulations

![46 食品级HA粉末 46 食品级HA粉末]()

Professional Application Solutions

1. Food Safety Assurance Solutions

2. Texture Optimization Solutions

3. Stability Enhancement Solutions

4. Regulatory Compliance Solutions

Certification Excellence & Food Quality

Complete Certification: cGMP, ISO9001, ISO22000, ISO13485, HACCP, HALAL, FSSC22000

Food Safety: Rigorous contaminant and microbial testing

Quality Consistency: Batch-to-batch performance verification

Global Compliance: Meets international food standards

5 Google-Optimized Q&A About Food Grade Sodium Hyaluronate

Q1: What food applications use sodium hyaluronate?

A: Food-grade sodium hyaluronate is used in functional beverages, dairy products, sauces, health foods, and dietary supplements for its moisture retention and texture properties.

Q2: How does food grade differ from other grades?

A: Food grade meets specific safety standards for human consumption, with stricter controls on contaminants and manufacturing processes under food-grade certifications.

Q3: What molecular weights are available for food use?

A: Runxin offers multiple molecular weights from 50kDa to 2000kDa, allowing selection based on desired viscosity and application requirements.

Q4: What documentation ensures food safety compliance?

A: We provide Food Grade Certificate, Heavy Metal Test Reports, Microbial Analysis, and complete regulatory documentation for food applications.

Q5: How is stability maintained in food products?

A: Through controlled processing parameters, proper storage conditions, and formulation optimization based on our extensive food application experience.

Food Application Solutions

Functional Beverages: Enhanced mouthfeel and stability

Dairy Products: Improved texture and moisture retention

Sauces & Dressings: Optimal viscosity and consistency

Health Foods: Functional ingredient incorporation

Dietary Supplements: Quality nutritional products

Food Technical Support

Application development guidance

Regulatory compliance assistance

Formulation optimization support

Quality documentation provision

Conclusion

Runxin's Food Grade Sodium Hyaluronate Solutions deliver reliable performance and safety for food applications, backed by comprehensive international certifications and 28 years of food ingredient expertise.

Contact Runxin for food-grade solutions, technical specifications, and application support services.

![01 01]()