Manufacturer Profile: Runxin – Advanced HA Modification Specialists Since 1998

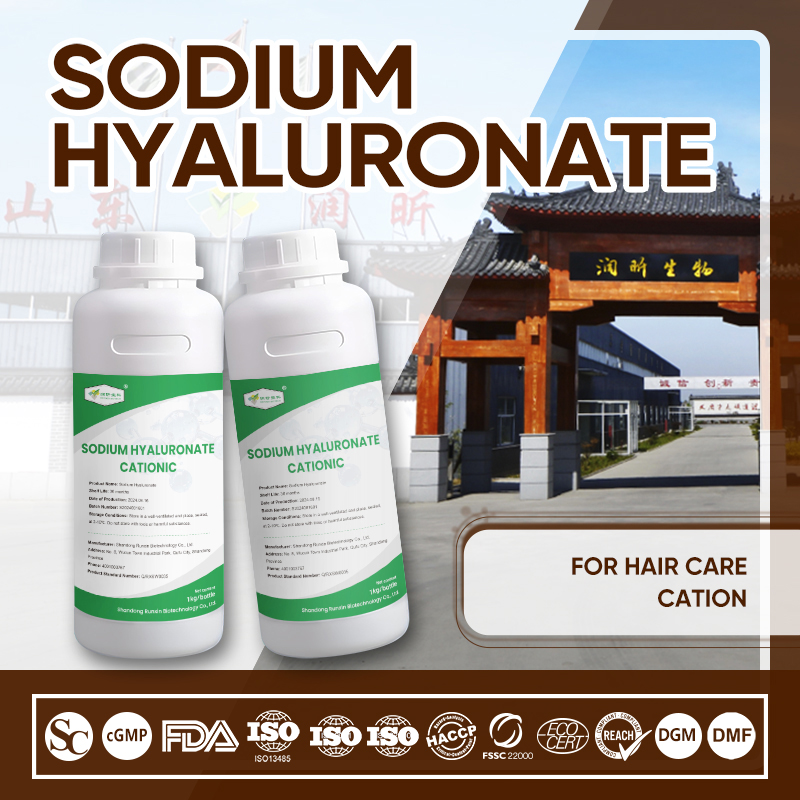

Runxin brings 28 years of pioneering expertise in bio-fermentation and molecular modification technologies for advanced sodium hyaluronate derivatives. Our state-of-the-art bioconversion facilities maintain comprehensive international certifications including cGMP, ISO9001, ISO22000, ISO13485, HACCP, HALAL, and FSSC22000, with specialized capabilities in cationic polymer synthesis. Serving innovative cosmetic, pharmaceutical, and personal care brands across 70+ countries, we combine proprietary fermentation technologies with advanced chemical modification processes to deliver cationic sodium hyaluronate with enhanced functionality and performance characteristics.

Product Overview: Cationic Sodium Hyaluronate

Runxin's Cationic Sodium Hyaluronate represents a breakthrough in hyaluronic acid technology through controlled molecular modification of bio-fermented HA. This innovative derivative features positively charged functional groups that significantly enhance substantivity to negatively charged surfaces like skin and hair. With a cationic degree of 15-35% and molecular weights ranging from 50,000 to 1,200,000 Da, our product delivers superior adhesion, improved film-forming properties, and enhanced delivery of active ingredients compared to conventional hyaluronic acid.

![03 03]()

Key Advantages

Enhanced Substantivity: Positive charge ensures superior adhesion to skin and hair surfaces

Improved Bioavailability: Increased cellular uptake and tissue retention

Multi-Functional Performance: Combines HA's moisturization with cationic conditioning benefits

Compatibility: Stable across wide pH range and compatible with anionic systems

Sustainable Production: Bio-fermentation derived with controlled modification process

Technical Specifications

Appearance: White to off-white fibrous powder

Cationic Degree: 15-35%

Molecular Weight: 50,000-1,200,000 Da (customizable)

Purity: ≥90% (HPLC)

Loss on Drying: ≤10%

Nitrogen Content: 2.0-4.5%

pH (1% solution): 4.5-6.5

Viscosity (1% solution): 100-2,000 mPa·s

Heavy Metals: ≤5 ppm

Microbiological Profile:

Solubility: ≥95% in water

Certifications: cGMP, ISO9001, ISO22000, ISO13485, HACCP, HALAL, FSSC22000

Applications

Hair care products for enhanced conditioning and anti-static properties

Skincare formulations requiring prolonged active ingredient release

Leave-on treatments with improved substantivity

Pharmaceutical delivery systems for enhanced bioavailability

Professional salon products with superior performance

Men's grooming products requiring strong adhesion

FAQs About Cationic Sodium Hyaluronate

What are the primary benefits of cationic modification for hyaluronic acid?

Cationic modification transforms hyaluronic acid into a positively charged polymer that strongly adheres to negatively charged biological surfaces like skin and hair. This significantly extends residence time, enhances moisturization duration, improves active ingredient delivery, and provides inherent conditioning and anti-static properties.

How does your bio-fermentation technology ensure consistent cationic modification?

Our proprietary bio-fermentation process begins with pure microbial-derived HA, followed by controlled chemical modification using quaternary ammonium compounds under optimized reaction conditions. This two-step process, monitored through advanced analytics, ensures consistent cationic degree and molecular weight distribution.

Can cationic sodium hyaluronate be used in combination with anionic surfactants?

Yes, despite its positive charge, our specially designed cationic HA demonstrates excellent compatibility with anionic systems when properly formulated. We provide specific guidance on incorporation methods and formulation protocols to maintain stability and performance in complex systems.

What makes cationic HA superior for hair care applications?

The positive charge creates strong electrostatic bonds with negatively charged hair surfaces, providing exceptional conditioning, reduced static, improved combability, enhanced shine, and prolonged moisturization effects that withstand multiple washes compared to conventional HA.

How does your quality management system support innovative product development?

Our integrated quality system, certified under cGMP, ISO9001, ISO22000, ISO13485, HACCP, HALAL, and FSSC22000, ensures rigorous control of modification processes, comprehensive characterization of final products, and complete documentation for regulatory compliance, supporting our customers' innovative product development needs.

Why Choose Runxin for Cationic Sodium Hyaluronate

28 Years of Modification Expertise: Extensive experience in HA derivative development since 1998

Proprietary Fermentation Technology: Pure bio-fermented HA as starting material

Controlled Modification Process: Precise cationic degree and molecular weight control

Sustainable Manufacturing: Environmentally responsible production methods

Complete Quality Assurance: Full certification under cGMP, ISO9001, ISO22000, ISO13485, HACCP, HALAL, and FSSC22000

Partner with HA Innovation Leaders

Choose Runxin for your cationic sodium hyaluronate requirements and leverage our 28 years of bioconversion expertise. Contact us today to request samples, technical documentation, or discuss your specific application challenges. Experience the transformative potential of cationic hyaluronic acid technology from a trusted industry pioneer committed to innovation and quality excellence.

![01 01]()