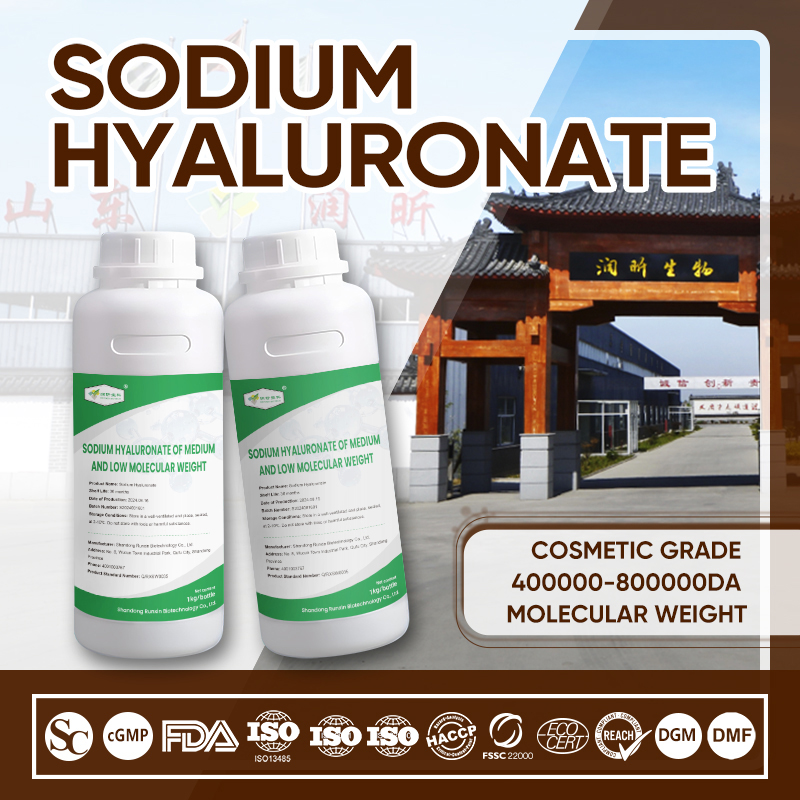

Manufacturer Profile: Runxin – cGMP Certified HA Specialists Since 1998

Runxin brings 28 years of manufacturing excellence in pharmaceutical-grade sodium hyaluronate production under strict cGMP compliance. Our advanced hydrolysis facilities maintain comprehensive international certifications including cGMP, ISO9001, ISO22000, ISO13485, HACCP, HALAL, and FSSC22000, with specialized expertise in mid-range molecular weight hydrolysis. Serving pharmaceutical, advanced skincare, and medical device manufacturers across 70+ countries, we combine cGMP manufacturing standards with precision hydrolysis technologies to deliver 400 kDa sodium hyaluronate with pharmaceutical-grade quality and consistent performance characteristics.

Product Overview: 400 kDa Hydrolyzed Sodium Hyaluronate

Runxin's 400 kDa Hydrolyzed Sodium Hyaluronate represents a pharmaceutical-grade mid-molecular weight HA produced under strict cGMP conditions. This precision-engineered product undergoes controlled enzymatic hydrolysis to achieve consistent 400 kDa molecular weight (±25 kDa), creating an optimal balance for formulations requiring both effective skin barrier penetration and sustained reservoir formation. The cGMP-compliant manufacturing process ensures exceptional purity, batch-to-batch consistency, and reliability for critical pharmaceutical and advanced cosmetic applications.

![03 03]()

Key Advantages

cGMP Certified Production: Manufactured under pharmaceutical-grade quality systems

Optimal Molecular Size: 400 kDa provides ideal balance of penetration and retention

Enhanced Bioavailability: Superior skin absorption with prolonged activity

Pharmaceutical Grade: Meets stringent quality standards for medical applications

Batch Consistency: Guaranteed molecular weight consistency through validated processes

Technical Specifications

Appearance: White to off-white crystalline powder

Molecular Weight: 400 kDa (±25 kDa)

Purity: ≥97% (HPLC)

Loss on Drying: ≤7%

pH (1% solution): 6.2-7.2

Viscosity (1% solution): 800-1,500 mPa·s

Protein Content: ≤0.03%

Heavy Metals: ≤3 ppm

Microbiological Profile:

Endotoxin Level: <0.05 EU/mg (for pharmaceutical grade)

Solubility: ≥99% in water

Particle Size: 80-150 mesh

Certifications: cGMP, ISO9001, ISO22000, ISO13485, HACCP, HALAL, FSSC22000

Applications

Pharmaceutical formulations for dermal drug delivery

Advanced anti-aging serums with sustained release

Medical device coatings and hydrogel systems

Professional aesthetic products

Regenerative skincare formulations

Ophthalmic preparations and wound care products

FAQs About 400 kDa Hydrolyzed Sodium Hyaluronate

What makes 400 kDa an optimal molecular weight for pharmaceutical and advanced skincare applications?

The 400 kDa molecular weight represents the ideal threshold for creating a sustained-release reservoir in the stratum corneum while allowing gradual penetration into deeper epidermal layers. This balanced performance makes it particularly valuable for transdermal drug delivery and long-lasting skincare efficacy, backed by clinical studies showing optimal residence time and bioavailability.

How does cGMP certification impact the quality and consistency of your 400 kDa HA production?

Our cGMP certification, integrated with ISO9001, ISO22000, ISO13485, HACCP, HALAL, and FSSC22000 standards, ensures rigorous process validation, comprehensive documentation, and continuous quality monitoring. This pharmaceutical-grade approach guarantees identical molecular characteristics, purity levels, and performance attributes across all production batches, which is critical for regulatory submissions and product consistency.

What specific advantages does 400 kDa HA offer for transdermal delivery systems?

At 400 kDa, sodium hyaluronate creates an optimal molecular network that enhances drug solubility, improves skin residence time, and facilitates controlled active ingredient release. Its molecular size allows efficient skin interaction without rapid clearance, making it superior for pharmaceutical formulations requiring precise dosing and sustained efficacy.

Can 400 kDa hydrolyzed sodium hyaluronate be used in sterile formulations?

Yes, our cGMP manufacturing process includes optional sterile filtration and aseptic processing capabilities. We provide low-endotoxin grades (<0.05 EU/mg) suitable for ophthalmic applications, injectable formulations, and other sterile products, with full sterility validation documentation available.

How do you ensure molecular weight accuracy and what analytical verification is provided?

We employ validated SEC-MALS (Size Exclusion Chromatography with Multi-Angle Light Scattering) methods with NIST-traceable standards for absolute molecular weight determination. Each batch includes comprehensive analytical documentation confirming the 400 kDa specification, molecular weight distribution, and intrinsic viscosity parameters to ensure pharmaceutical-grade accuracy.

Why Choose Runxin for 400 kDa Hydrolyzed Sodium Hyaluronate

28 Years of cGMP Manufacturing: Pharmaceutical-grade production expertise since 1998

Precision Hydrolysis Technology: Validated processes for accurate molecular weight control

Comprehensive Quality Systems: Full certification under cGMP, ISO9001, ISO22000, ISO13485, HACCP, HALAL, and FSSC22000

Regulatory Support: Complete documentation for pharmaceutical submissions

Technical Excellence: Expert guidance on formulation and application development

Partner with Pharmaceutical-Grade HA Specialists

Choose Runxin for your 400 kDa hydrolyzed sodium hyaluronate requirements and benefit from our 28 years of cGMP manufacturing expertise. Contact us today to request samples, analytical certificates, or discuss your specific pharmaceutical and advanced skincare applications. Experience the reliability of pharmaceutical-grade hyaluronic acid from an industry leader committed to quality, consistency, and innovation.

![原料详情页1 原料详情页1]()